Frequently Asked Questions

Silver Point Transfer Needles are meant to be paired with a suitable Luer lock syringe. Select a suitable syringe and press the needle’s hub firmly into the Luer taper, rotating clockwise until resistance is met to lock the needle onto the syringe. Only once the needle and syringe are paired should the needle’s protective sleeve be removed. Always examine the needle and syringe for defects before use. Supporting both the needle and the syringe with both hands, liquids can be transferred from one container to another. The extended length Silver Point Transfer Needles are springy and dangerous “snap-back” may occur if not properly supported. When finished, the entire needle and syringe should be disposed of in an appropriate sharps container. Do not re-sleeve needles.

Our needles were specifically designed to be used with solvents and most harsh reagents encountered in the lab. Strong mineral acids may corrode the steel needles. Testing with common organic solvents exhibits no degradation after a 4-hour period.

It has been suggested that plastic and stainless steel do not adsorb significant quantities of water and thus do not need to be dried.1 We have run a variety of water-sensitive reactions with Silver Point Transfer Needles and have found that even at small scale, no noticeable change in reaction outcome is observed.

1. Chandra, ACS Chem. Health Saf. 2022, 29, 175–183.

1. Chandra, ACS Chem. Health Saf. 2022, 29, 175–183.

All used needles must be treated as hazardous sharps waste and should be disposed of in a suitable sharps container in accordance to federal, state, and local regulations.

Silver Point Transfer Needles were designed as a disposable product and should not be reused.

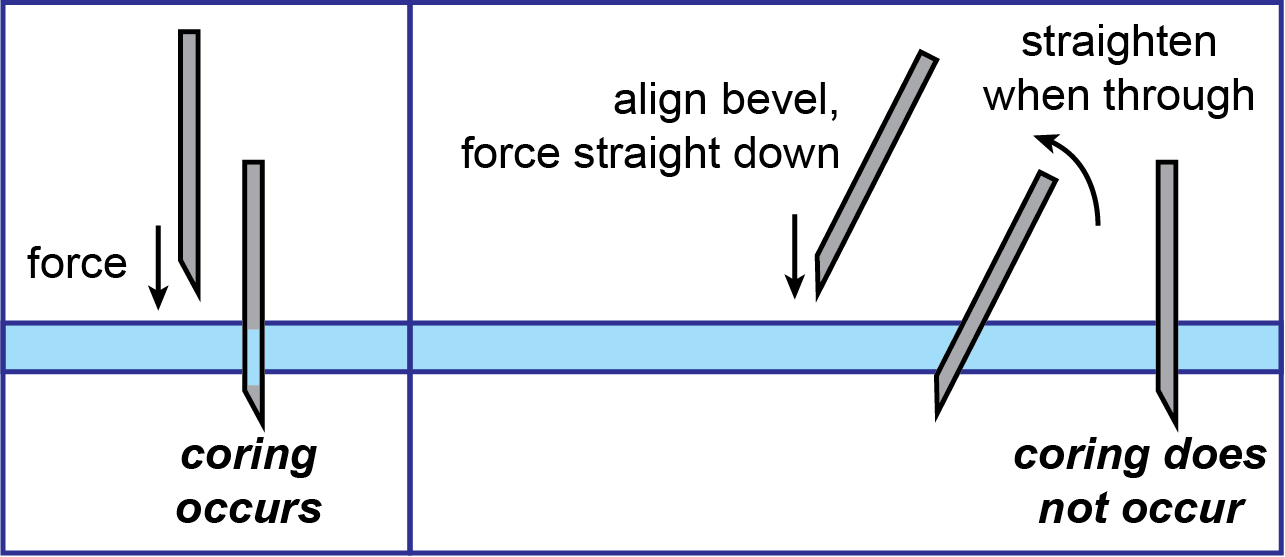

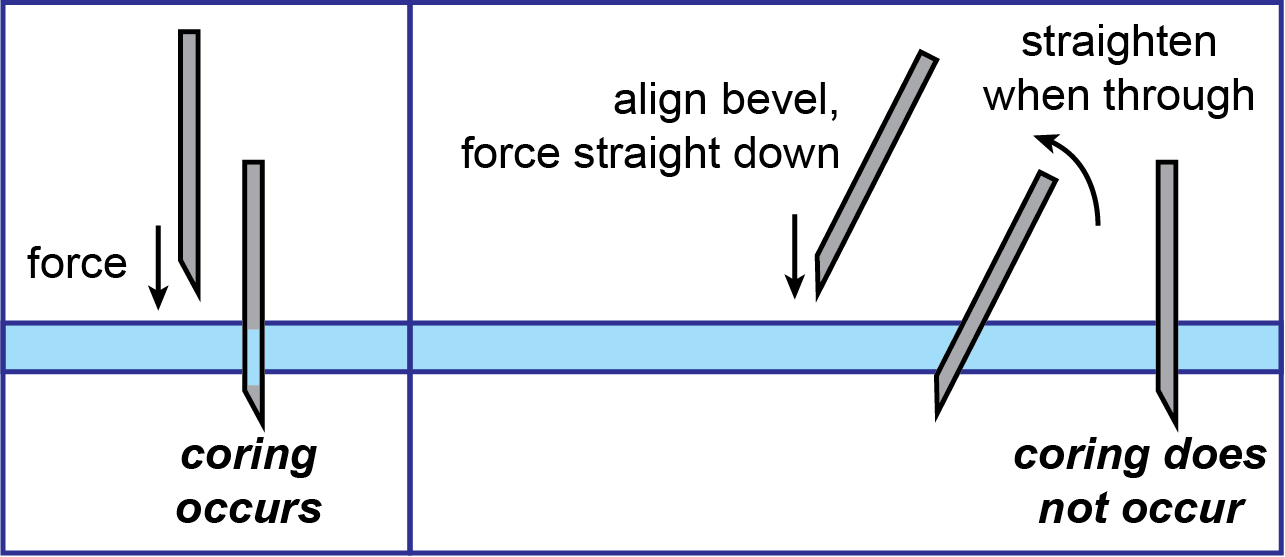

Coring occurs when a needle unintentionally cuts a small circle out of the septum it is being used in. This rubber “plug” clogs the needle and compromises the integrity of the septum. We have found this to be an issue with nearly all needles available on the market. However, coring can be easily prevented by slightly altering the angle of insertion.